|

The vertical jets were now removed

to allow for the extraction of the rear corridor box section. These

were just glued into holes in the base and could be twisted free. One piece

of pipework under the jet was missing and there were kit parts in the area

it occupied which would seem to indicate that the part fell off during

the first series and was not replaced.

The boxes and

underside VTOLs are taken apart and cleaned...

All of the aluminium parts on the model

needed cleaning with Brasso metal polish, especially those which seemed

to be coated in a layer of concrete dust.

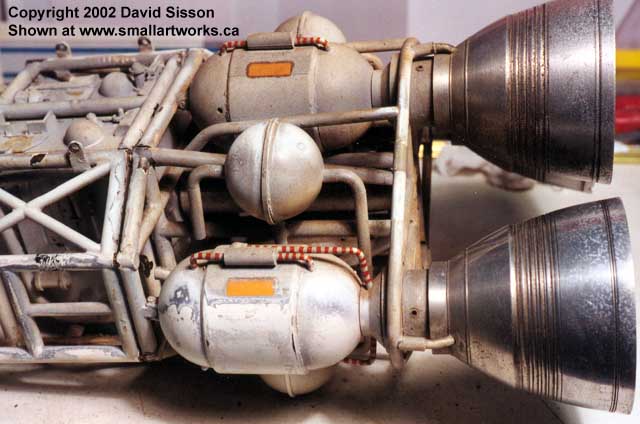

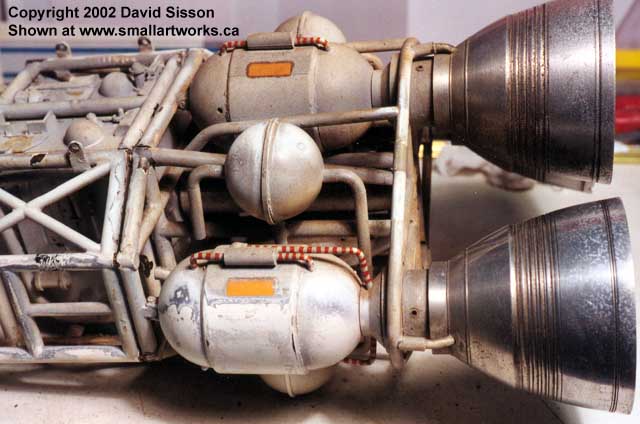

The parts of the large combustion chamber

tanks in front of the bells were all loose because they are only dressing

and not structurally sound items. The domes are EMA (a.k.a. Plastruct)

products and the middle cylinder is solid wood. The small bracket at the

front that connects to the rear cage is actually soldered to a length of

¼" brass tube that runs all the way into the base of the engine

bell, so the combustion chamber just has a hole drilled down the centre

and hangs on it. Most of the thin piping running over the surface of these

parts is just plastic coated wire, bent to shape and simply pressed into

position. These "plumbing" tubes and parts around the engine section on

the model as they exist today barely resemble the configuration that was

in place when the model was originally built. This area of the model underwent

extensive modifications throughout the run of the series.

|

Small Art Works tech note...

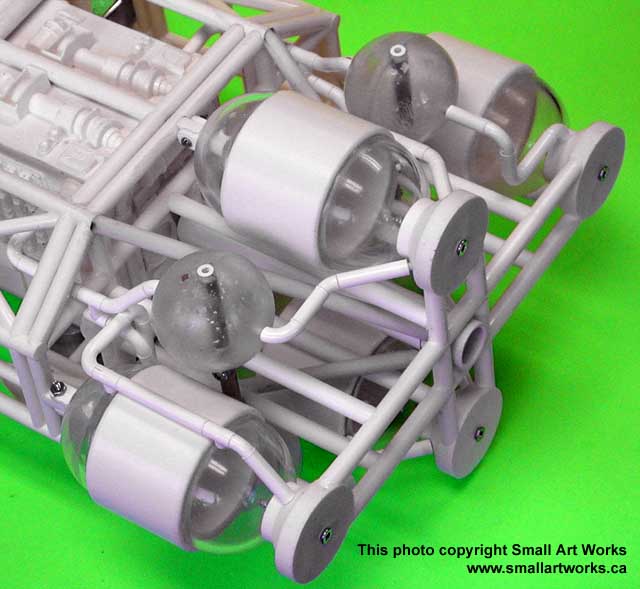

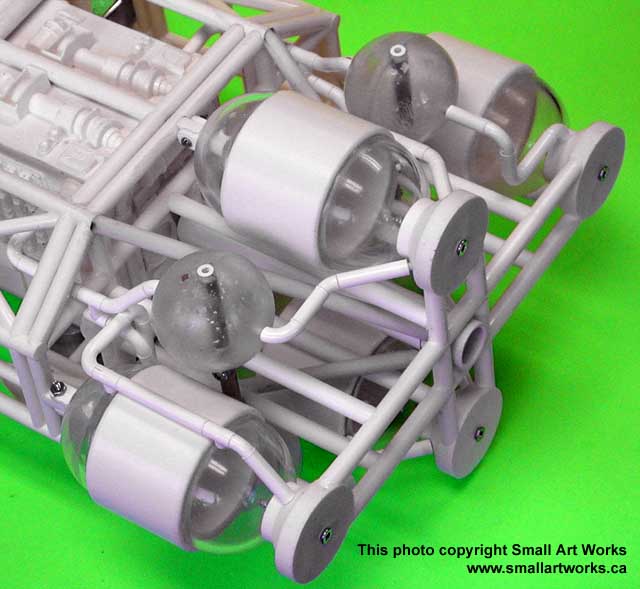

Below is a picture of an unfinished

44" Eagle replica under construction by Small Art Works for a customer,

showing what the "plumbing" or piping configuration would have looked like

when the #1 Eagle model was originally built. (Special thanks to Chris

Trice and Daniel Prud'Homme for the information necessary to accurately

construct this replica.)

Now, back to David Sisson with his restoration

article...

|

One point of interest design wise is that

the top and bottom chambers don't fit properly without alteration, something

I discovered when I built a replica and thought I'd gone wrong. The middle

core butts up against the supports running between the rear cage and the

cross member frame, so two deep groves are cut into the wood to allow the

chambers to fit in place.

The two smaller tanks, above and below,

are again EMA domes but this time glued to a central brass disc that is

soldered to a connecting tube. The pipes coming out of the front and rear

are just lightweight plastic tubes and bends which together with many of

the parts on the shelves inside the cages can still be found in the EMA

catalogue.

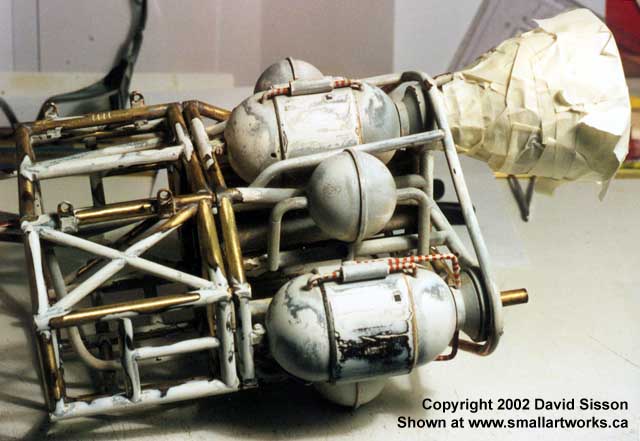

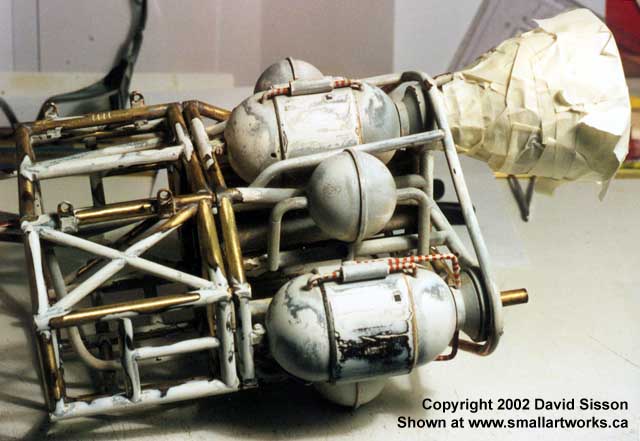

With the rear corridor section and vertical

thrusters removed, the bottom framework fell out quickly followed by the

small right hand side fuel tanks. The model had obviously received a heavy

blow to this area in the past that had twisted the right engine out of

line and broke the cross member support. So many pieces of pipe were loose

on the back of the cage that I thought it might all fall apart, so I quickly

identified the most important connections and soldered them back together

again to give the unit some rigidity while I then attempted to straighten

it all up.

One by one all the broken joints were cleaned

of accumulated paint and soldered back together again, a job made slightly

tricky because I couldn't remove the plastic and wood combustion tanks

which did get a little bit singed in a couple of places. All the parts

fitted back in position, only one piece of brass pipe was missing and had

to be replaced, but it proved impossible to completely straighten out the

unit and there's still a few kinks in there.

Rear section almost ready for painting.

The wooden combustion chambers had a number of splits running along their

surfaces which needed filling and then smoothing over and quite a bit of

loose paint that needed chipping off. Note the four notches on the cages

upper most length of brass pipe. All four cage sections were numbered in

this manner by the original model maker.

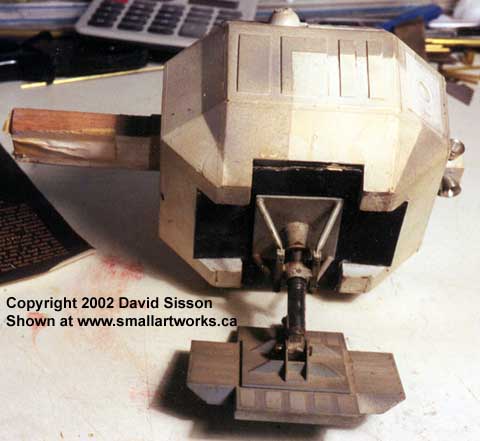

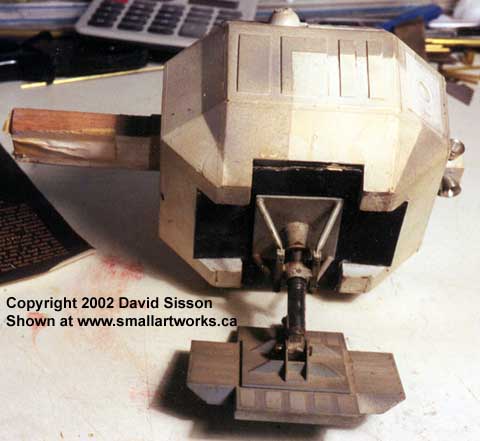

With the frame now fixed I turned my attention

to the shoulder pods. These are made from wooden blocks that are clad in

thin perspex and then detailed with grey ABS plastic sheeting and kit parts.

Over the years the action of the glue and paint has caused some of the

thin perspex panels to warp and lift away from the wood and several just

fell off.

In the past I had noticed, in some publicity

photographs, that the landing gear assemblies were occasionally twisted

and so I thought they were damaged. However these parts are simply pushed

into a hole, so they can easily rotate or be pulled out, and were just

held in position with double sided tape.

Each pod is partially hollowed out by four

large holes that are covered by a plasticard plate again attached using

tape. In the right hand hole you can just see a brass tube that runs into

the back of the attitude thruster block which can also be rotated and pulled

out.

On the left hand side of the pod you can

see the wooden support that plugs into the frame. All of these are a bit

loose but this one (front left) has been sanded down in size, possibly

for the episode 'The Exiles' when it was plugged into the 2nd 44 inch Eagle

model, and it is now covered in masking tape to make it fit properly. Also

note that the four small lower corners are just painted wood and are not

covered in plastic.

Continued...

|